Explosion-Protected Camera for Petrochemical and Energy Infrastructure

ATEX-Style Explosion-Resistant Camera for Oil, Gas, and Chemical Plants

Product Overview

This Explosion-Proof Industrial Camera is engineered for reliable video monitoring in hazardous and explosive environments where conventional imaging equipment cannot be safely deployed. Designed with a fully sealed, reinforced metal housing, this camera is suitable for continuous operation in areas containing flammable gases, vapors, combustible dust, or volatile chemicals. It is intended for industrial safety systems, process monitoring, and security surveillance in high-risk facilities such as refineries, chemical plants, oil & gas installations, mines, and fuel storage areas.

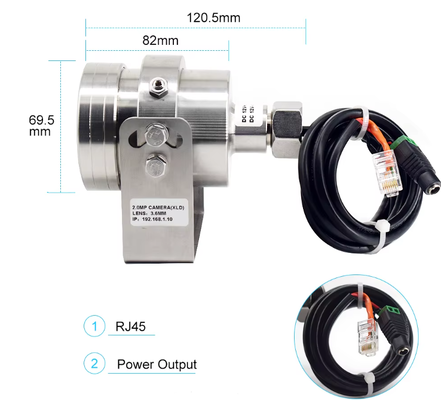

The camera adopts a mechanically robust cylindrical structure with precision-machined metal components and reinforced fasteners, ensuring resistance to pressure, vibration, impact, and corrosion. Its design philosophy prioritizes intrinsic mechanical protection, thermal stability, and long-term operational reliability in environments subject to extreme conditions.

Mechanical & Structural Design

The camera body is manufactured from industrial-grade stainless steel or high-strength alloy metal, providing excellent resistance to corrosion, chemical exposure, and mechanical stress. The thick-walled cylindrical enclosure is designed to withstand internal pressure fluctuations and external impacts, minimizing the risk of ignition or structural failure.

A sealed optical glass window is integrated into the front housing, protecting the internal imaging module while maintaining optical clarity. The lens window is precision-fitted and secured using reinforced fastening points to ensure airtight sealing and resistance to vibration.

A heavy-duty mounting bracket allows stable installation on flat surfaces, structural frames, or custom industrial fixtures. The bracket supports fine angle adjustment, enabling precise field-of-view alignment during system commissioning.

Explosion-Proof & Environmental Protection

This camera is designed to meet the structural requirements commonly expected in explosion-proof and hazardous-area installations. The sealed enclosure prevents external flammable gases or dust from entering the internal electronics compartment, while the robust housing contains potential internal sparks or thermal energy.

Key environmental protection characteristics include:

- Fully sealed metal enclosure to prevent ingress of gas, dust, and moisture

- High mechanical strength to resist shock, vibration, and impact

- Corrosion-resistant surface treatment, suitable for outdoor and chemical environments

- Industrial waterproof sealing, allowing operation in rain, wash-down, or humid conditions

This makes the camera suitable for both indoor hazardous zones and outdoor industrial deployments, including offshore platforms and exposed installations.

Imaging & Optical System

The camera integrates a high-stability industrial image sensor optimized for continuous operation and consistent image output. The optical system is housed entirely within the sealed metal body, isolating sensitive components from environmental contaminants.

The front lens assembly is designed for stable light transmission and minimal distortion, supporting reliable monitoring of equipment, pipelines, valves, and operational zones. Depending on system configuration, the camera can be integrated into analog or digital video transmission architectures, making it compatible with a wide range of industrial monitoring systems.

Electrical & Signal Integration

The camera is equipped with a sealed industrial cable interface, ensuring secure signal transmission while maintaining enclosure integrity. Internal wiring is isolated and strain-relieved to prevent fatigue during long-term operation.

The design supports OEM system integration, allowing the camera to be deployed as part of:

- Explosion-proof CCTV systems

- Industrial safety monitoring platforms

- Process control visual inspection systems

- Hazardous-area access monitoring solutions

Power and signal specifications can be adapted to match project-specific requirements, making the camera suitable for custom engineering applications.

Reliability & Long-Term Operation

This explosion-proof camera is engineered for 24/7 continuous operation in environments where maintenance access may be limited or hazardous. All mechanical and electrical components are selected to withstand prolonged exposure to:

- High temperatures and thermal cycling

- Mechanical vibration from heavy machinery

- Corrosive atmospheres

- Moisture, dust, and particulate contamination

The result is a low-maintenance, high-reliability imaging solution suitable for mission-critical safety and monitoring systems.

Typical Applications

- Oil & gas refineries and processing plants

- Chemical production and storage facilities

- Mining operations and underground installations

- Fuel depots and tanker loading zones

- Power generation plants

- Industrial safety and explosion-risk zones

- OEM hazardous-area monitoring systems

Technical Specifications

| Item |

Specification |

| Product Type |

Explosion-Proof Industrial Camera |

| Housing Material |

Stainless steel / high-strength alloy |

| Structural Design |

Fully sealed cylindrical metal enclosure |

| Explosion Protection |

Mechanical explosion-resistant structure |

| Environmental Protection |

Waterproof, dustproof, corrosion-resistant |

| Lens Protection |

Reinforced optical glass window |

| Mounting Type |

Adjustable heavy-duty metal bracket |

| Installation |

Fixed industrial mounting |

| Operating Environment |

Hazardous / explosive industrial areas |

| Vibration Resistance |

Industrial-grade shock and vibration resistance |

| Cable Interface |

Sealed industrial cable outlet |

| Operation Mode |

Continuous 24/7 operation |

| Application Type |

CCTV, safety monitoring, process observation |

| Customization |

OEM / ODM configuration supported |

Designed for environments where safety, durability, and reliability are non-negotiable, this explosion-proof camera provides a robust visual monitoring solution for hazardous industrial zones. Its reinforced metal construction and sealed optical system make it an ideal component for long-term deployment in mission-critical safety and surveillance systems.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!